A home’s entry way and exterior door can influence how efficient the residence is. Doors that are improperly sealed can leak air, causing energy waste that can drive up your utility bill. This is especially true for old, worn, uninsulated, and improperly sealed doors.

The traditional new home construction process has given general contractors (GCs) a bad rap. Typically, clients would work with an architect to design their dream home, only to be stunned when construction bids from GCs come in way over budget and timelines stretch. Patterson Custom Homes aims to restore faith in GCs by beginning its relationship with clients as early as possible in the process.

As builders implement digital technology into day-to-day operations, they’re seeing improvements in communication like high-touch customer service and efficiencies like onsite virtual inspections.

In part one of our two-part series to help remodelers maintain success, we discussed mapping productivity processes, upselling by downselling, tracking local leading economic indicators, and more. In this post, we explore building relationships with suppliers, minding your cash flow, and speaking the language of style and design.

Successful remodelers are confident optimists by nature. They’re strong leaders, excellent communicators, fair and timely. These traits boost reputations and fuel business, even in uncertain times, like the Great Recession and the pandemic.

Over the years, the traditional Craftsman has evolved, incorporating features of modern styling, especially for its interior layouts. To help you guide the conversation with buyers, dealers, and architects, we wanted to spotlight some of our favorite Modern Craftsman window and door design ideas.

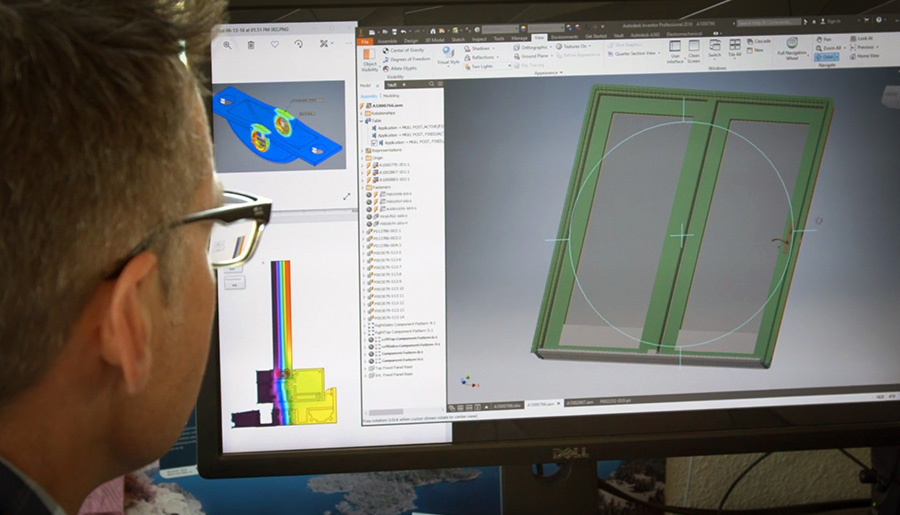

The JELD-WEN research and development (R&D) center in Klamath Falls, Oregon, is our hub for innovation, science, technology, and design testing . This tech center is where we’ve established many of the performance ratings that make our doors and windows stand out and stand up to the elements in different geographic areas. Using 3D design and printing capabilities on-site allows us to test materials and products early in the development process. To ensure our products meet and exceed the demands of real-world conditions before being released, they are tested, refined and put through their paces here. It’s a tried-and-true approach for delivering a total solution. That includes the installation phase, too. Easy-to-follow instructions that everyone can understand are all part of the process behind releasing new and improved products. See how our process comes together. Watch the video below. Learn more about JELD-WEN® windows, exterior doors and interior doors.

In the fourth and final installment of our series on wood windows, we will address how windows can be modified to incorporate products from related industries to improve the performance of very different buildings.

“Build tight, ventilate right” is a mantra among high-performance builders. Their homes are highly insulated and tightly sealed to prevent drafts and include efficient mechanical systems and well-insulated windows to maintain clean, comfortable indoor air. But where does the moisture go?

BIM is an approach to design and construction. It’s built around a digital model of the home and draws on a database that spans costs, engineering specs, and schedules — a one-stop resource.